Imagine you walk into ASEPT’s R&D lab in Lund, and you will hear it before you see it, the sound and click of pumps being tested, again, again and again. A million strokes, to be exact. The engineers lean over workbenches dotted with 3D-printed prototypes, containers of sauces, and mechanical rigs built to push materials to their limits. It is here, in this constant cycle of testing and tweaking, that “smarter” dispenser pumps are born.

Because for ASEPT, a smarter pump is not just one that dispenses perfectly. It is one that listens. Listens to the chef who’s tired of messy portions, to the operator working and prepping at 6 a.m., to the brand that wants cleaner lines, less waste, and greater sustainability.

Every innovation starts with a conversation

A customer told one of ASEPT’s engineers about the endless hours their team spent filling thousands of soufflé cups by hand. Another explained the challenge of pumping thick, chilled sauces without clogging or jamming.

Instead of simply improving an old design, ASEPT went back to the drawing board. “We didn’t want a slightly better pump,” says Nils Hellzén, R&D Manager at ASEPT. “We aimed to create a pump that truly raised the bar for performance.”

That mindset led to the Portion Pump MAX. A redesigned solution shaped by real-world insights. With its floating piston, it can even work upside-down in chilled environments and still handle chunky sauces. This is clever engineering born not from a whiteboard, but from observing how people really use food pumps in the field.

Prototype. Test. Break. Repeat.

Once an idea takes shape, the fun begins, and by “fun” ASEPT’s engineer team means punishing prototypes until they fail.

Every new pump faces at least a one-million-stroke challenge before it is approved. It must deliver the same portion, every time, no matter the viscosity, temperature, or number of particulates in the product. Engineers run cold tests, heat tests, and even “sticky sauce” stress tests to ensure performance across every scenario.

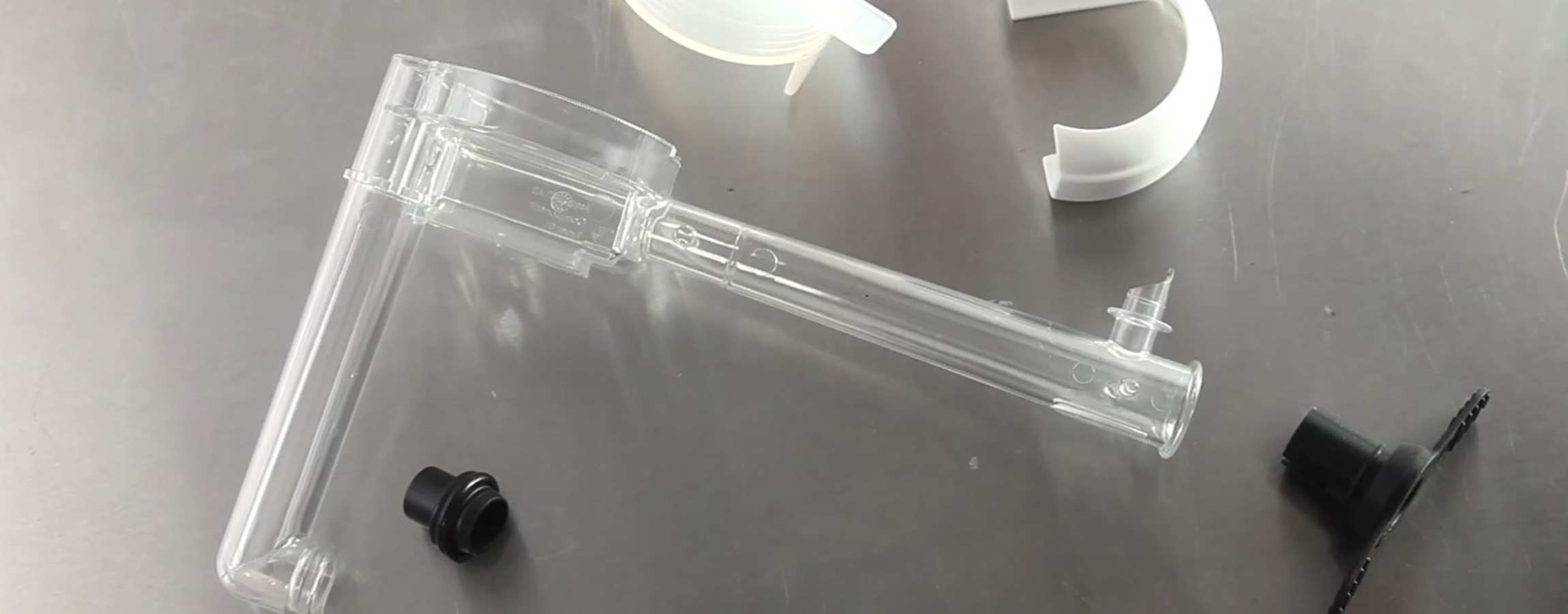

Thanks to in-house 3D printing, new components can go from idea to physical part within hours. If a test fails, a redesign might be printed and mounted the same day. “It’s all about iteration, we learn fastest when you get the 3D-printed parts in your hands, and you could test them in the lab” says Nils Hellzén.

Building smarter from the inside out

So, what exactly makes a pump “smarter”? It is not about electronics or fancy displays. It is about engineering intelligence using design, materials, and mechanics to solve real problems.

- Precision | Every press delivers the same amount, cutting waste and saving time.

- Reliability | Millions of cycles without failure, under multiple test conditions.

- Hygiene | Minimal food contact parts, easy to clean, transparent housing for visual checks.

- Sustainability | Reduced product waste and recyclable materials built into the design.

- Adaptability | Custom solutions for brand, product, and environment customer specifications.

This is a sort of “quiet innovation”. The kind that hides inside something simple, but makes everything around it works better.

Collaboration is the secret ingredient

At ASEPT’s lab, knowledge flows freely between engineers, designers, and customer specialists. It is not a hand-off, it is a continuous exchange where ideas evolve through collaboration across departments.

A project might start with a sketch and a story from a customer. From there, ideas travel back and forth: drawings, tests, feedback, prototypes, more tests. Every department adds its expertise, whether it is precision molding, materials testing, or visual design.

The result? A product that does not just work in theory, it works where it matters.

The future of dispensing

As ASEPT looks forward, the team’s focus remains the same: smarter design through better understanding.

Future pumps may incorporate connected sensors, data feedback, or automated refilling, but the core philosophy would not change. Every innovation begins with a simple question: What does the customer need, and how can we make it easier, cleaner, and smarter to deliver?

Behind every smooth pump of sauce, there is a story of engineering grit, long hours, and endless testing. That is the heart of ASEPT’s smarter food pumps built not just in the lab, but hand-in-hand with the people who use it every day.