At ASEPT, innovation is our daily reality. Right now, our R&D department is in one of its most intense and exciting phases to date, with multiple projects in motion and fresh concepts steadily advancing the future of food dispensing technology.

A Period of Intense Development

Our engineers are currently deep in the process of prototyping, testing, and refining ideas that will soon redefine standards in hygiene, efficiency, and ease of use. This is not just about launching new products—it’s about solving real challenges faced by food producers and restaurants every day.

New Concepts in the Pipeline

From smarter dispensing systems that minimize waste to designs that simplify kitchen workflows, the ideas emerging from our dedicated team reflect a strong customer focus and a deep understanding of the foodservice environment. While we cannot reveal everything just yet, what we can say is: game-changing solutions are coming!

Turning Customer Needs into Innovation

Some of our most exciting developments have come directly from listening to customer pain points—observing workflows, understanding inefficiencies, and turning those insights into functional, future-ready solutions.

Example | Automating Repetitive Prep Tasks

One common challenge across the foodservice industry is the labor-intensive process of manually filling thousands of soufflé cups with signature sauces each day. It is time-consuming, repetitive, and adds up in labor costs.

In response, our team is developing an automated system that takes over this task. It drops each soufflé cup, dispenses the correct portion of sauce, and then moves the filled cup to a staging area for final prep—such as applying lids or flavor labels. Built to integrate seamlessly with our Condimatic drive system this solution is a direct answer to a real operational need, combining efficiency with adaptability.

Example | Adapting to Cold Storage Needs

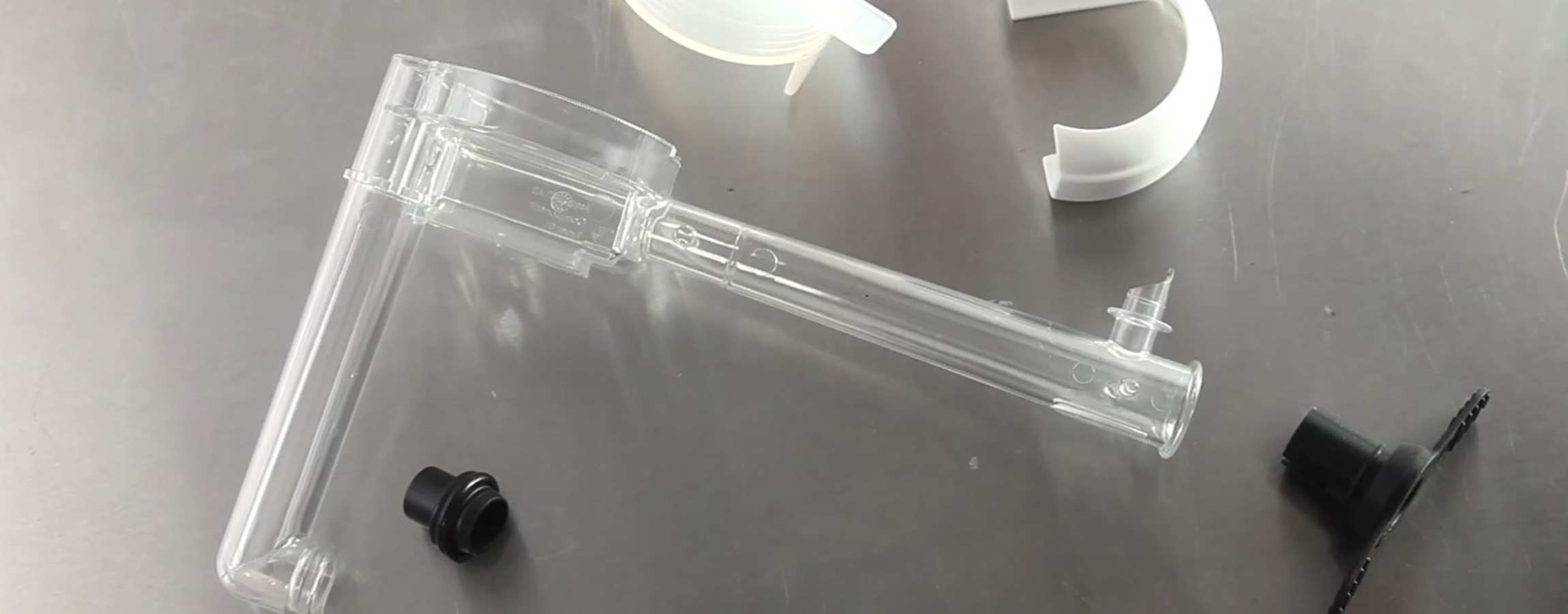

Another innovation grew out of feedback from long-time users of our Portion Pump system. While the existing solutions delivered on portion control and reliability, customers wanted the ability to store and serve sauces directly from a chilled unit—without compromising the product or the dispensing performance.

The result is the Portion Pump MAX—a hand-held pump system built around a floating piston. This allows the unit to operate inverted in a cold well, maintaining food safety while still handling sauces with particulates. It’s a compact, efficient tool designed with real kitchen demands in mind, solving both waste and consistency concerns in one system.

Collaboration is Key

Innovation at ASEPT is a team sport. Engineers, sales, assembly, and customer support all play a role in shaping our new solutions. Feedback from users is part of every development stage—ensuring our products are not only technically advanced but truly relevant and easy to implement in daily routines.

A Word from Our R&D Manager

“Our team is driven by a genuine passion for problem-solving,” says Nils Hellzén, R&D Manager at ASEPT. “We are innovating to make a real difference for our customers. Every concept we work on is guided by insights from the field, and every engineer here understands the impact our solutions can have in a busy kitchen or food production line. It is a collaborative, fast-paced environment, and I am incredibly proud of the creativity, dedication, and user-focus our team brings to the table every day.”

A Glimpse of the Future

Stay tuned in the coming months as we begin to share more about what is in the work. We are excited about what is ahead—and we think you will be too!