With the EU’s Single‑Use Plastics (SUP) Directive now in force, reducing plastic waste is no longer optional, it’s a legal requirement and an important step toward more responsible foodservice operations. The directive bans many single‑use plastic items and encourages reusable or refillable systems to reduce waste and support circularity.

Foodservice operations face two major waste problems – and both affect cost, efficiency, and sustainability commitments:

- Product Waste | Leftover sauces and condiments trapped in bottles, jars, or containers that never reach the customer.

- Packaging Waste | Single‑use plastics that harm the environment and no longer comply with new EU sustainability regulations.

How ASEPT’s Sealed Dispensing System Reduces Waste

ASEPT’s Sealed Dispensing System are engineered to help operators cut waste, improve efficiency, and support sustainability goals.

1. Near‑Total Product Yield

Traditional squeeze bottles and jars often leave around 15% of product unused, increasing both waste and cost. ASEPT’s Sealed Dispensing System achieves up to 98% product yield, ensuring nearly every drop is dispensed.

2. Controlled Portions = Less Overuse

Over‑portioning is a frequent source of unnecessary waste. ASEPT dispensing systems provide precise, consistent portions, helping operators:

- Maintain recipe accuracy

- Reduce overuse

- Improve cost control

- Deliver consistent servings that keep guests happy

3. Fewer Refills, Less Downtime

Larger pouches mean less packaging material compared to traditional buckets or jars. They also require fewer refills, keeping service efficient, especially during peak hours in high‑volume kitchens.

Supporting Sustainability and EU Compliance

The EU SUP Directive bans single‑use plastic products such as: Cutlery, Plates, Straws and Expanded polystyrene (EPS) food containers and cups.

ASEPT’s Sealed Dispensing System support compliance by:

- Eliminating single‑use portion packs

- Reducing plastic waste through bulk packaging formats

By switching to ASEPT’s Sealed Dispensing System, operators can:

- Reduce product waste with up to 98% yield

- Cut packaging waste and meet EU sustainability requirements

- Improve operational efficiency and control food costs

Ready to Reduce Waste in Your Operation?

Discover more about our Sealed Dispensing System and explore our full range here.

With ASEPT, it’s easy to reduce waste, stay compliant, and boost efficiency in any kitchen.

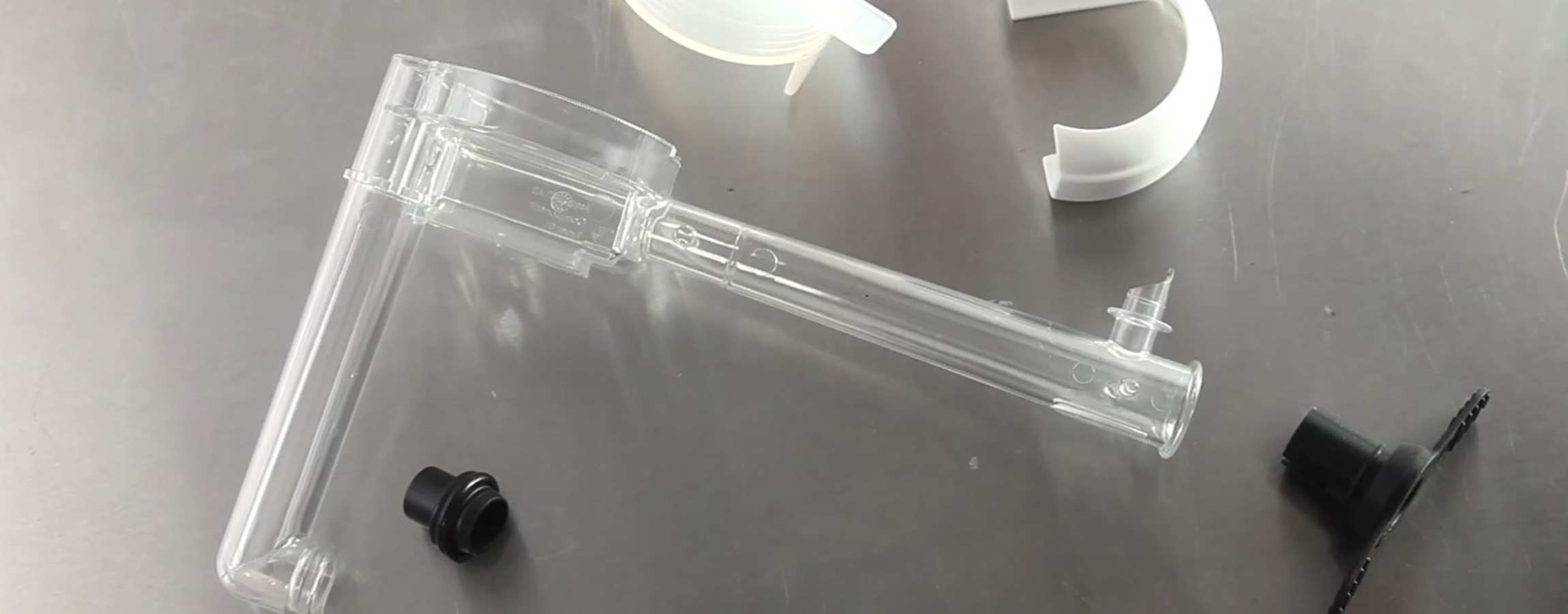

New Product Spotlight | A handheld pump with Maximum yield!

Our new handheld Portion Pump MAX sets a new industry benchmark with up to 99% product yield, powered by its vacuum‑primed technology.