MAKING A DIFFERENCE

WITH SUSTAINABLE PACKAGING SOLUTIONS

Environmental responsibility is becoming increasingly vital, and as members of the foodservice and personal care industries, we are dedicated to supporting waste reduction and lowering pollution.

We know that single-use packaging for food and beverage products significantly contributes to excessive waste and pollution. But what practical options are there?

At ASEPT, we support the shared goal of sustainability by developing dispensers, including pouched product dispensers, pumps and handheld options. Our focus is on crafting products that support eco-friendly packaging and address your operational needs effectively. We specialize in helping businesses transition seamlessly from single-serve portion packs to bulk dispensing systems. Together, we can positively impact the environment. Making the transition leads to economic benefits and a significant reduction in waste.

Single-Use Packaging

Addressing Our Environmental Impact

The Ellen MacArthur Foundation reports that the global packaging industry produces approximately 311 million tons of plastic packaging each year, a figure that’s expected to rise. If trends continue, there could be more plastic than fish in the ocean by 20501. Much of this plastic comes from food and beverage packaging. ASEPT embraces our responsibility to reduce packaging waste in the markets we serve.

1 World Economic Forum, Ellen MacArthur Foundation and McKinsey & Company,

The New Plastics Economy — Rethinking the future of plastics

OUR ENVIRONMENTAL COMMITMENT AND GOALS

Environmental stewardship is prioritized in all of ASEPT’s operations. Holding ISO 14001 certification is a testament to our commitment to meeting the highest environmental management standards. It requires ongoing sustainability improvements and underscores our mission for a more sustainable future.

With that said, all ASEPT products are designed with the end user in mind. Each solution is crafted to endure demanding service environments, promote sustainability and offer exceptional efficiency. Whether you’re a restaurant owner, sauce producer or operations manager, choosing ASEPT means investing in eco-friendly solutions that help reduce waste, improve yield and lower costs. The benefits are clear: better product utilization, reduced environmental impact and a commitment to greener practices throughout the product lifecycle.

Designing Solutions for Sustainability

Sustainability is genuinely embraced at ASEPT and is not just a claim. Our products are built to withstand harsh conditions, maximize performance and minimize environmental impact. ASEPT Pouched Dispensing Systems, our foremost product line, are designed for superior product evacuation, ensuring up to 98% yield and reducing waste. Customers benefit from fewer refills, lower costs and a cleaner operation. Additionally, our focus on recyclable materials and durable construction supports sustainable disposal practices, ensuring both operators and the planet benefit.

With ISO 14001 Certification, Everyone Benefits

- Reduced Resource Consumption: Optimized production processes improve efficiency and reduce environmental load.

- Efficient Energy Use: We use energy-smart methods to minimize waste and reduce emissions.

- Smarter Procurement: Environmentally conscious purchasing strategies support sustainability from the ground up.

- Lower Costs for Waste Management: By reducing waste, we lower the costs of waste handling and disposal.

While achieving ISO 14001 certification is a significant milestone, our commitment to continuous environmental improvement is ongoing. Every proactive step we take brings us closer to a more sustainable future. Together, we can ensure food safety in an eco-friendly way.

The Recycling Component of ISO 14001 Certification

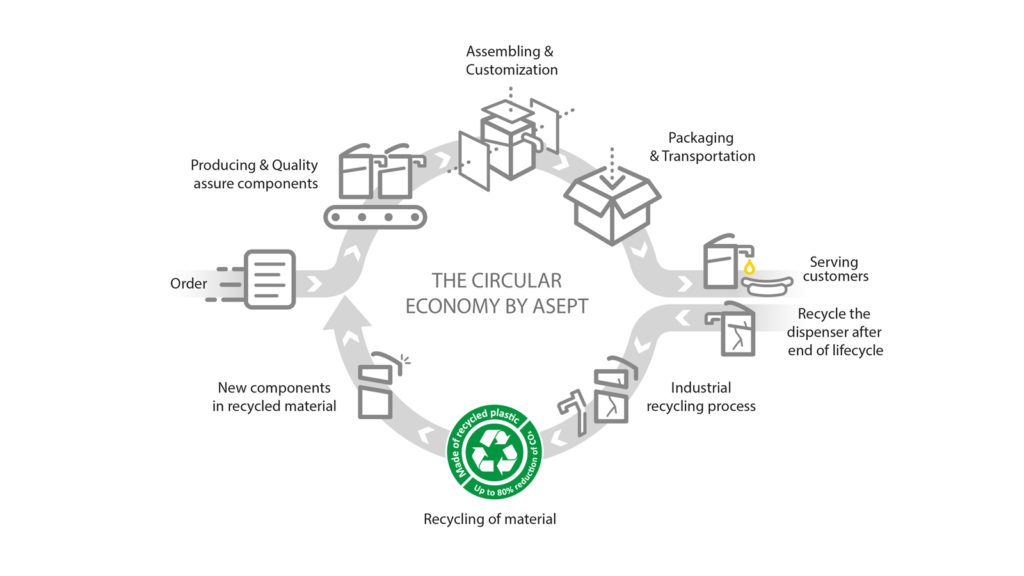

TURNING USED PLASTIC INTO NEW PRODUCTS | THE CIRCULAR ECONOMY

Recycling is essential to reducing CO2 emissions and minimizing waste. We are proud to contribute to the circular economy. Even products with an extended lifecycle eventually reach the end of their use. When this happens, the materials in our dispensers should be recycled to prevent them from becoming waste. By reprocessing these materials, plastic can be repurposed to create new dispensers, significantly reducing the environmental footprint of our products.

Recycling Process and Material Integrity

For effective recycling, dispensers should be clean and free from food residue. Our products are made from advanced plastics and polymers commonly used in the automotive, medical and electronics industries. These materials are chosen to ensure the durability and quality expected from ASEPT dispensers. Once sent to an industrial recycling plant, the materials are shredded and melted into pellets, which can be used to replace virgin materials in the production of new plastics. Importantly, all parts in food contact zones are made from virgin material to meet the strictest food safety standards.

Environmental Impact: Up to 80% CO2 Reduction

Recycling plastic dramatically reduces the greenhouse gas emissions associated with producing virgin materials—from oil extraction to final manufacturing. The process results in a potential average CO2 reduction of up to 80%*, highlighting the value of sustainable recycling practices.

*(Note: This CO2 reduction is an estimated average. Source: World Economic Forum, Ellen MacArthur Foundation, and McKinsey & Company, The New Plastics Economy.)

Your satisfaction depends on our high standards! To see how we consistently deliver top-notch quality, check out our Testing & Quality page.